Nurses in neonatal intensive care units (NICUs) often spend a significant portion of their shift waiting for breast milk to defrost, so they can prepare bottles for their hungry patients. This inefficiency not only wastes precious time but also results in substantial labor costs for hospitals every year. BBy is revolutionizing this 70-year-old freeze-and-defrost process with its innovative technology that converts donor breast milk into shelf-stable, powdered breast milk.

A Problem Worth Solving

According to Dr. Vansh Langer, CEO of BBy, the current system is a "huge opportunity" to transform the way hospitals store and administer breast milk. He estimates that this issue costs hospitals millions of dollars in labor each year, emphasizing the need for a more efficient solution.

The Science Behind BBy’s Technology

Langer founded BBy in 2015 with bioengineer and food scientist Blanca Rosa Aguilar Uscanga, PhD. The duo drew inspiration from Uscanga’s research paper on creating powdered breast milk that retains its bioactive elements. Together, they developed a two-factor laser device that works in conjunction with commercial condensers.

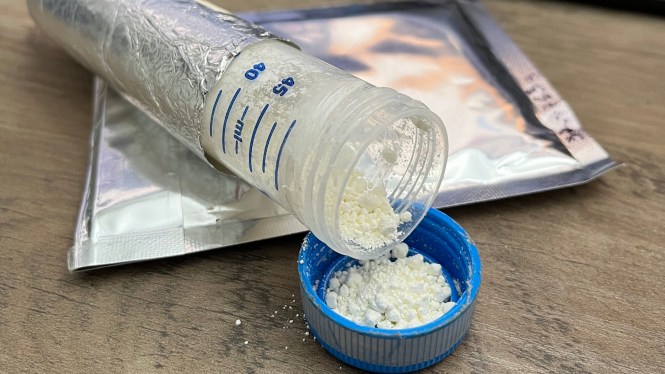

The device utilizes an algorithm created by Uscanga to adjust the rate and temperature of the breast milk being processed. This ensures that the resulting powder remains within what Langer calls the "bioactive zone," thereby preserving its nutritional and immunological properties. The powdered breast milk is shelf-stable for up to six months, eliminating the need for frequent defrosting and reducing waste.

A Scalable Solution

BBy packages the powdered breast milk in one-ounce and two-ounce aluminum packets, which are delivered to hospitals every two weeks. Nurses can then simply mix the required amount of powder with water to prepare a feeding. This streamlined process not only saves time but also reduces the need for multiple freezers to store large quantities of breast milk.

A Growing Presence in the Healthcare Industry

BBy processes 10 gallons of breast milk twice daily at eight regional processing facilities located near its 17 client hospitals in Massachusetts, Connecticut, and Texas. The company’s main research facility is situated in Guadalajara, Mexico. BBy’s technology has garnered significant attention, with over 50 related peer-reviewed and published scientific articles.

Patent-Pending Technology and FDA Designation

The U.S. Food and Drug Administration (FDA) has designated BBy’s technology as a food device, exempting it from further medical review. The company’s patent-pending status underscores its commitment to innovation and intellectual property protection.

Financial Performance and Future Growth

BBy has achieved impressive revenue growth, averaging $800,000 per month and approaching $10 million in annual revenue. Langer expects this figure to double within the next year as hospital contracts are finalized, despite the long sales cycles inherent in the healthcare industry.

Bootstrapping and Recent Funding Round

After seven years of bootstrapping, BBy secured $3 million in a funding round last year, following its participation in various accelerators and incubators. This investment will facilitate further expansion and development of the company’s technology.

Conclusion

BBy’s breakthrough technology has the potential to transform the way hospitals store and administer breast milk, saving time, reducing waste, and minimizing labor costs. With its innovative solution and growing presence in the healthcare industry, BBy is poised for continued success and growth.